« The video is ready! | Front Page | Shipping update ... »

Old printing workshop

Posted by Dave Bull on May 6, 2020 [Permalink]

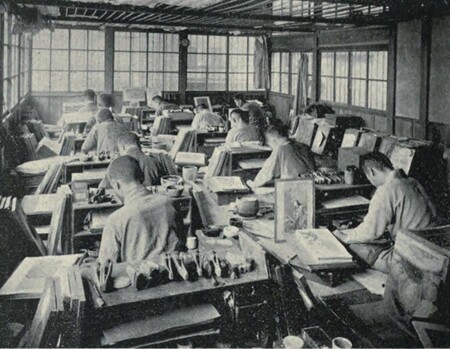

Look at this astonishing photo!

The photo came to me from Wikipedia, and purports to have been taken in 1910, in the woodblock printing workroom for the company that published the art magazine Kokka.

I learned about the existence of this photo today from one of the commenters on the newest YouTube video. For those who aren't familiar with it, the magazine Kokka has been published off and on since the Meiji era, and in its early days included woodblock prints in each issue. This was in the time before easy colour printing by offset presses, so in order to illustrate the old art that was the topic of the magazine articles, woodblock print reproductions were used to show the readers what the original items looked like. Because it was a popular magazine, they thus needed a lot of woodblock prints!

I have quite a few of the prints from old Kokka issues here in my collection, and the quality is sometimes nothing short of unbelievable. How on earth did they actually work to such fine tolerances? ... how did they carve so finely? ... It has all just seemed a bit unreal. But as you can see from this photo, it was basically pretty simple - just teams and teams of very highly skilled craftsmen, beavering away at their work day after day ...

We can glean so much from this photo ...

- None of the printers are using the maru-bake brushes (the ones similar to shoe-brushes in shape) that every printer uses these days. Every single brush visible in this photo is of the hanga-bake type (with the 'vertical' handle, and the hair in a single clump).

- There is no artificial light at all; in winter, work in this room must have ended pretty early every afternoon ...

- How on earth did these guys get in and out of their workstations?

- The strings across the roof show that this room must also have been used for drying paper after the sizing process. Perhaps they all did such work together? It seems impossible that sizing and hanging could co-exist with printing ...

- The stacks of prints being made are not protected in any way from drying out; is this really moistened paper?

- Every single piece of wood visible is perfectly flat and straight - presumably freshly carved for the current month's magazine. Once printing was done ... what happened to them? Tossed out, I suppose ... Some of them do seem a tad thinner; perhaps they were planed down for a second use ...

Added by: Marc Kahn on May 6, 2020

I'm counting 12 workstations (including the foreground one) and 11 printers in this picture. Do you think that they did a "production line" with each printer doing one impression/color and then passing the work-in-process to the next station? If not, and each printer did all of the impressions, how many blocksets would have to be carved to accommodate the current issue's print insert?

What year do you suppose this was?

Added by: Dave on May 6, 2020

If … each printer did all of the impressions …

It can’t have been done that way. Those Kokka prints have many many dozens of impressions - far more than we can even count - and given the quite large circulation of the magazine, the work of making those prints must have been distributed, with many men working on the same image.

But on the other hand, in the photo, we see the closest two men working on prints of a different dimension, and the third man up in the right-hand group with yet another one. So there are at least three different prints under construction here (and of course they could all be different …)

Added by: Karl on June 6, 2020

Hhmm. Wonder if that's not the bulk era full blown.

Thanks for posting the pic .

Add Your Input