« Knife update ... | Front Page | Knife set - handle prototyping »

Knife set - next step

Posted by Dave Bull on January 30, 2012 [Permalink]

A 'prototyping' day yesterday - one of the most enjoyable parts of any project!

I myself have nothing to do with the actual making of the blades themselves. Beyond discussing the type of steel to be used, and the tempering, etc., I won't be touching that stuff. Of course.

But the 'accompaniments' - handles, storage box, shipping container, pamphlet, etc. - all fall within my purview. And as we are really starting completely from scratch, everything is wide open. I'm trying to get work done on all these things, bit by bit, and yesterday it was the turn of the storage box to get my full attention. I spent the entire day down at the worktable in the shop, surrounded by small hand tools and a pile of paulownia wood offcuts.

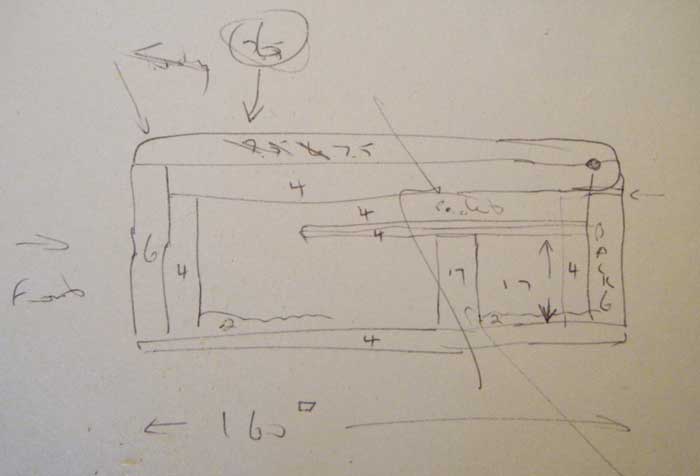

This was the starting point:

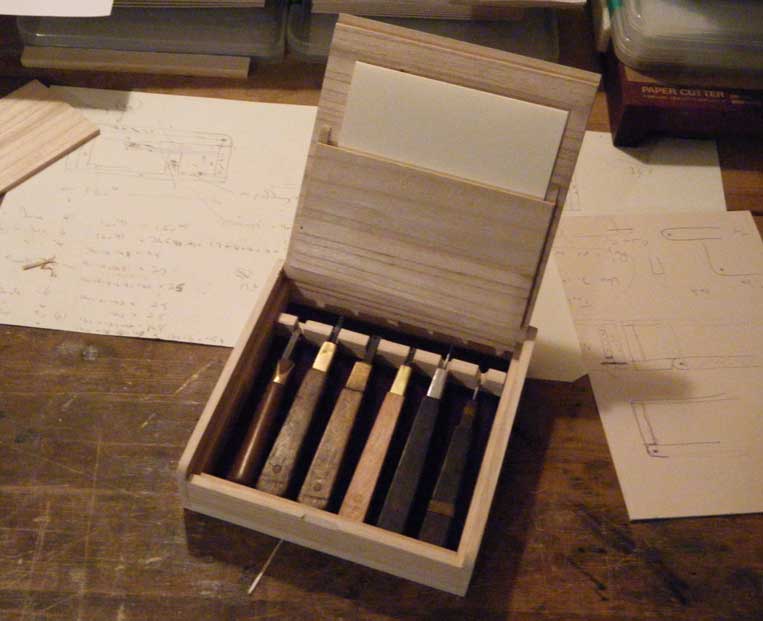

That's not much of a 'plan', and if I passed it to somebody else to build, they'd just scratch their head. But a couple of hours later, it was coming along well. Here's an interesting shot - a box in a box!

What's this? We're including a set of carving tools inside the next Treasure Chest? Well no ... it was just that the new Treasure Chest sample box that was near at hand on the bench was the perfect thing to use as a gluing jig for this new little box ...

After the glue was set, the basic shape of the box was visible:

Next step was to fashion the lid. There are three basic approaches possible for that: a lift off-on top like those on most tool boxes of this type, a sliding top, or one that is hinged.

I decided to try making a hinged lid, but as I don't want to use hardware, I made this first prototype with wooden pin hinges. Here's the result (front view):

And the back ...

Pretty nice, I think! Don't look too closely, because the workmanship is a bit rough, but this is just a prototype ...

I then grabbed a piece of cloth for the inside, chopped a quick 'n dirty tool support, and put a few of my own tools inside. (Note that this selection does not represent the selection that will be in the actual set.)

Not so bad ... That pocket in the lid is for the CD-type booklet that will have information on the tools, their history, and their maintenance. But now that I see it 'done', I think it looks a bit 'top heavy'. We'll have to have a bit of a re-think here perhaps ...

(Comments on that would be appreciated - do you think it is necessary for the booklet/pamphlet to be stored in the case itself?)

The open space on the underside of the booklet slot would be the place where the label gets pasted: 'Mokuhankan - fine prints and tools', our address, etc., along with the name of the person who ordered the set, the date of manufacture, and the 'serial' number.

I'll take this with me to the Tuesday meeting with the knife maker, and in the meantime, I'd better get working on the design of the shipping carton, because that is going to take time to receive after placing the orders. (Or no, perhaps I should get some work done on the website for the upcoming print series ...) (Or no, perhaps I should work on the expansion of the Mokuhankan bookkeeping system to encompass this new venture ...) (Or no, perhaps I should make that visit to the employment office I have been postponing - I have got to get a helper/manager here!) (Or no, it's time to get down to the lumber market at Kiba to find a supplier for the paulownia wood for the cases for the new series ...)

(etc. etc. etc.)

But no. Today it can be none of the above. I have to get some paper wet for the second batch of printing on the final Mystique print ... and I have to do that right now!

Added by: Mark Mason on January 30, 2012, 6:48 pm

I don't think the proud owner of this set (I'd like to add my name to the list, if I can manage the price) would need daily access to the printed info, so I would consider dropping that support shelf and putting the info booklet under the knives, out of the way.

But, I could also see that little storage area being very useful to store a spare knife blade, wrapped in cloth, or a piece of leather strop.

Regarding finish, I would consider a very dark stain to the box.

Added by: Tom Kristensen on January 30, 2012, 10:05 pm

Looking mighty fine Dave, but I'll throw couple of ideas at you. I guess there are two ways to go here; a presentation box that shows all the contents off nicely, or a box that is perhaps more utilitarian.

For what its worth I was supplied with a similar support in the box that contained my original set of 11 tools and I removed it early on. I found it was too fiddly to put the tools in and out of the support while carving. That box came with a loose lid which can be used as a tray and is handy for spreading the tools out while working. Plus I ripped out the cloth that lined the box because it was picking up all the fine shavings and I thought the timber looker better. When I travel I need to secure the lid with a rubber band. All in all its not a great system, I really need a bigger box.

For my money a simple spacious box that will take extra tools is the way to go.

As far as the cd goes I think it will end up pretty dusty if it lives in the box for ever, but in my ideal box the cd and paperwork could live in an insert tray that would then serve as extra storage for those extra tools. After all, If this venture succeeds, as it should, there is every chance you will be issuing other tools that will need to a home to squeeze into. Everybody needs a clearing chisel or two and a kento nomi.

Added by: Dave on January 30, 2012, 10:13 pm

if I can manage the price ...

Sato-san would be upset with me if I shared any of the numbers just yet. I'm not trying to be coy about this, but given that we still have no solid total on our costs yet, it would not be fair to any of us (potential customers, or ourselves) to put certain expectations on the table.

These new knives will clearly end up being more expensive than the ones in the Baren Mall. The back-of-the-envelope pricing that we have been able to calculate so far makes that clear. But without question, these are going to be a whole different class of tool. Does that mean you should be ready for a major sticker shock? We don't think so.

At this point all I can say is that we are going to price these things from 'the bottom up' - totting up all the component and associated assembly costs, and then putting a very basic margin on top of that. As we move forward, we expect that we will attain some degree of savings from getting more efficient at the process, and that's when we hope our margins will get healthier.

Anyway, it shouldn't be too long now. The costs for the blades themselves should be worked out in tomorrow morning's negotiations. After that it will be the costs for the handles and the box that will make up the next largest chunk. Once those two items are decided, we'll probably be able to set our prices, at least for starting ...

Added by: Dave on January 30, 2012, 10:24 pm

a similar support in the box ... and I removed it early on. ... I ripped out the cloth that lined the box ...

Tom, so the tools are loose and rolling around?

As far as the cd goes

I think you've misunderstood something I wrote earlier; there is no CD involved here. I just used the comparison to show the size that our little booklet will be.

For my money a simple spacious box that will take extra tools is the way to go.

Having room I understand; having the tools 'loose' is not something we want to encourage. Here's a photo from my upcoming newsletter - taken in the Takumi workshop. It's carver Asaka-san:

The tools are all in drawers - pulled open for the photo - and he has picked out the ones he currently needs, and placed them on his bench. Absolutely no chance of any tools banging each other and chipping or nicking.

Added by: Michael Kohne on January 30, 2012, 10:40 pm

I think you do need to find a way to keep the booklet in the box - otherwise it will go missing pretty rapidly (as someone who's lost the instructions for pretty my everything he's ever owned, I can speak with some experience here).

If the booklet is in the box, but out of the way, it will likely stay in the box until needed.

Does the lid open any further than shown in the picture? If it doesn't, then what you've done is probably fine, but if it does open further, you'll have a risk of the booklet sliding out.

Good luck!

Added by: Barbara Mason on January 31, 2012, 2:51 am

Dave,

I use those stupid clear tube sections to put on the tool tips when I put them away...I have to hunt to find the ones that match up with the tool...it is really irritating. I think a bigger box would be better, but I find carrying them around that the clear tube sections really works well, so see no real reason for the slots to hold the tools....

However, I have not had a box like that so maybe I would use it.

I am really excited to get these "new tools" so add my name to the list of anxious buyers. I really hate the canvas wrap...somehow I just cannot make that work for me. I would need one several feet long and want the tools only on one side, the double sided one is really a pain and the slots are never exactly right...maybe I need to mark them as to which tool goes where.

Added by: Tom Kristensen on January 31, 2012, 6:37 am

Bad habits, I have a few... When I carve I am switching tools pretty often and I confess I do not put each tool back in the box each time I make a switch. So, I actually have tools loose on my bench, which is why I like the square handles, this prevents the tools from rolling around. I suspect I should start being more careful and if the new tools have round handles they will have to be returned to the box. I guess I will learn to deal with the tool support.

I like the look of Asaka-san's box, with the drawers sliding out the front. It would be possible to design a box that was a single drawer but was able to piggyback another copy of itself. That way additional drawers could be bought to house additional tools and a tower like this one could be built. Dave, you might remember the Lee Oscar harmonica boxes which could slide together to make a single rack.

Added by: Dave on January 31, 2012, 7:09 am

add my name to the list of anxious buyers

Barbara, why anxious!? You won't need a mortgage for these, I promise you! But if you mean 'can't wait', then welcome to the club! Sato-san and I are first in line - we can't wait to see these!

Does the lid open any further than shown in the picture?

In this first knock-together, it flips open 180 degrees, lying flat facing backwards. When I get time to make the next sample, I'm thinking about moving the hinge point forwards (one of the sketches on the table shows this) so that when open, it stands up at about the same angle as one of my Mystique cases.

stupid clear tube sections

Not stupid at all ... it's very important to protect the tips, obviously. I don't use them day-to-day, but if I have to carry a tool somewhere, I use one of these to protect it.

I do not put each tool back in the box each time I make a switch

Nor do I (or any pro carver here). As you can see in the photo above, you take out the ones you will be needing in the short term, and put them on the bench.

if the new tools have round handles

The knife will of course be round, but the chisels will not roll. That's fundamental for a pro tool here (because of our use of slanted benches).

It would be possible to design a box that was a single drawer but was able to piggyback another copy of itself.

This sort of idea is pretty long term for us. There are lots of possibilities, but given how much we have on our plate just now, we're going to concentrate on the tools themselves for the most part. I rather suspect the market for a tool 'tower' would be fairly limited!

Added by: Carole Dwinell on January 31, 2012, 11:14 am

It looks wonderful.

If I might add a comment about the clear tubes. Think Sharpie. Write the size ie 1.0 mm, and a 'V' or a U' or a 'CH' (chisel) or a BN (bullnose) on the tube. Whatever works for you. Same info on the tool. That way the clear tube goes right back on the tool that it belongs with.

Lining up tools in the canvas carrier works good if you start on the side where the ties are (assuming we're talking about the one from McClain's) with the smallest tools and work both top and bottom slots all the way across to the other end. I have 23 carving tools in the large size canvas carrying wrap. Since I take them to a class every week, that portability is quite nice, fits in a wood tote that my son made for me in a wood shop class in the '80s!

Added by: Patti Phare-Camp on January 31, 2012, 12:35 pm

ooooohhhh...am i reading about my birthday present for this year! When do you anticipate release of the set?

Added by: Dave on January 31, 2012, 2:35 pm

When do you anticipate release of the set?

It's still impossible to say. When we first floated this idea a month or so ago, we casually said 'Let's get this going by April,' that being the month when everything here in Japan gets going (school year, employment contracts, retirements, etc.)

But I don't think it's going to take that long. The steel part of the equation is pretty much settled, the boxes certainly won't take long (once the design is settled), and making the web pages etc. is trivial. The major 'problem' facing us is getting the handles made.

The place we've talked to so far isn't really looking all that enthusiastic about our ideas. Our design is 'different' from what they are used to - no brass sleeves for one - and if I had to guess at this point, I'd guess that we are going to end up making all the handles ourselves.

And 'ourselves' means me. At first anyway, as I prepare a bunch of jigs and tools for the job. The handles are not so complex, but they are not going to be trivial to make, with different angles in three dimensions, etc. etc.

And we have an interesting idea for the branding - for putting our name on them - and that is something else that might take a bit of time to sort out.

When I worked back in the music store, one of my biggest problems was that our owner would get on the phone with a customer, and promise that we could get something for them in (say) a week. It was then up to the rest of us to deal with the customer when it still wasn't there a couple of weeks later. When it was my turn on the phone, I would be promising a customer (say) three weeks, and the boss would hear this and chew me out. "They're going to hear that, and go somewhere else to get it!" He didn't care about being late with the delivery, as long as we got the order.

Anyway, in our case here, we're not worried that people will go somewhere else to place their order; this obviously isn't that kind of business. So let's leave it with our 'promise' to have them ready by April, with the good chance that it won't take that long.

Added by: william grix on February 2, 2012, 6:30 am

Hi Dave

I don't know how much information you plan for your booklet, but perhaps you can print in right on the the inside of the lid, never can lose or have to store that way., just a thought

Bill

Added by: Dave on February 2, 2012, 8:01 am

There will be way too much information to fit on a simple label; we're going to include some general background on Japanese tools, a discussion of why the steel in these tools is 'special', and of course a section on maintenance and sharpening.

Added by: Julio Rodriguez on February 4, 2012, 3:23 am

It all sounds pretty exciting Dave, glad you are sharing and letting us in in the developent of the whole enterprise. I am sure these tools are going to be big winners !

Added by: cem on September 20, 2016, 10:59 pm

Hi I am looking for 1 mm V 30 degree woodcut cutter can ı buy from you also do you produce professional wood block?

Thank you very much.

Add Your Input