« 30 years! | Front Page | Doi collaboration video - Part 8 »

Paper Breakthrough?

Posted by Dave Bull on July 26, 2016 [Permalink]

A fan from Germany dropped by the shop yesterday afternoon (on his once-a-year trip to Japan), and one of the first things he asked me was "How's the paper situation?"

It's been a few months since I made a couple of blog posts talking about the problems we have been having with both woodblocks and paper. The woodblock situation is basically under control at the moment, after working out a way to make our own blocks using some cherry I found in the wholesale lumber market. We're not out of the woods yet, as there is still no stable source of supply, but at least we now have the technology here to make the blocks, given a basically decent raw material.

Paper has been more difficult. As I posted last month, I have been experimenting with a 'machine' to do the sizing - allowing me to get a deeper, smoother size coating than by using a brush. This has helped in two ways: 1) some of the unusable paper has turned out to be printable, after sizing with this new method, and 2) if I can develop a more stable version of my little machine (Mark II), sizing should be doable by any of our staff members. This will give us a huge advantage as we move forward to the future; we wouldn't have this very tight bottleneck in our process, where a specific step can only be done by one specific (and highly-trained) person here ... (me). If other staff members can do a decent job on the sizing, it will be a major advance.

But. As I mentioned, only some of the bad paper responded to this treatment. The papermakers finally responded to my request to open discussion on this, and agreed to exchange 500 sheets of the 'bad' paper (they still don't admit there is anything wrong with it). They sent 500 new sheets; I returned the previous batch. That paper is useable, and we've been working through it now for the past month or so.

We're still sitting on over 500 sheets of the larger takenaga size paper, which they have made no similar offer on. But I haven't yet paid for those either, so it's a kind of stalemate at the moment ...

Anyway, while all this has been going on, I have been contacting workshops up and down the country, asking for samples of their paper. Most of these have - as expected - not even been remotely useable for printmaking, but a couple have seemed promising.

But something happened last Monday to put this whole adventure suddenly onto a faster track. My Facebook feed showed a link from one of our 'friends' to the page belonging to a paper making workshop, and the particular post in question (it's in Japanese) had an interesting content.

The young man who is the master of the workshop had been awarded a designation as a 'Master Traditional Craftsman' by some government group a few years back. That wasn't the content of the Facebook post; the content was more surprising - he was returning the award, and no longer wished to be associated with such a group. Some of our long-time fans will understand why at this point my ears perked up, but there will probably be newer fans who need a bit of background.

I myself have absolutely no interest in preserving traditions. This is sometimes a surprise to people, many of whom seem to think that this is the purpose of my life. Rather than get into an extended discussion here on this page now - because I want to talk about this papermaker - you can read to the bottom of this page, which I see from my files has been up on my website since 1997! :-)

For now, let's get back to the papermaker. To make a long story at least a little bit shorter, I dug deeper into this man's information and activities - from his website and Facebook - and what I learned sent me straight to my phone. "I'm coming from Tokyo to see you. Is next Tuesday OK? Good. See you then!"

"Next Tuesday" was today, and I am now back in Asakusa digesting the day's activities. This guy is nuts. Nothing else to say; he's as crazy as I am.

Why did he break free from the 'Master Craftsman' group? "That's not the way it's done." "You don't need to have your equipment so clean; we're just making paper ..." "You can't grow your own mulberry ..." This is the kind of thing 'they' told him; and the more he heard this kind of talk, the stronger his resolve became. His resolve to make paper like none that has been made before.

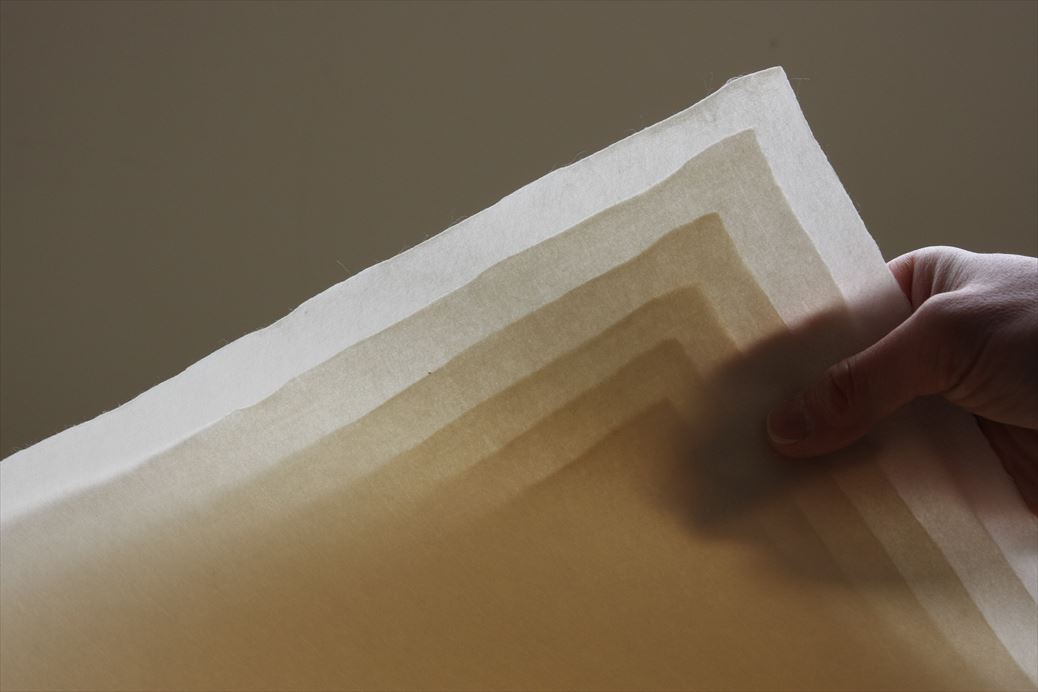

He's now 36, and in his very clean and well-organised workspace he's producing a very beautiful - and extremely 'neat' and clean - paper. No formaldehydes and preservatives. No additives. Just 100% mulberry and hibiscus root, just as in the old days. No dust, no dirt, no rust; all the bark scraps removed. Beautifully rocked to a perfectly smooth and even surface. It's gorgeous stuff.

Can I use this beautiful paper? No. It's far too thin, and has nowhere near the strength that we require for printmaking. His customers are people making lampshades, and shoji screens, etc. etc.

I had with me a number of paper samples:

- our current paper

- samples showing the current 'feathering' problems

- samples showing the current huge problems with bark scraps

- a stack of our prints; some nice ones, others spoiled by poor paper quality

And I also took with me a few sheets of paper from my storage shelves; rare paper from nearly 30 years ago. There was the model for his new experiments.

Nothing is going to change for me overnight. He's a busy man, and of course he has to take care of his current business. He can't just drop everything to play with me. But is he interested in trying to produce a paper that we could use? Yes, yes, and yes again.

Stay tuned!

* * *

Here are a few photos of the place, and of the work ...

Added by: Dave on July 27, 2016, 12:19 am

There is way more that I could have written about in that post. Honestly speaking, they are a pretty small outfit, and I doubt very much that they could handle our requirements, even should the experiments turn out successfully.

He's not interested in growing massively, but he is interested in developing his business the same way that I am with mine - to 'grow' it to a level where there is enough volume of business - and enough people working there - to put things on a fairly stable basis.

So I'm already thinking ahead a bit here. If his stuff looks good, and we start placing good orders with him, he'll need to obtain a much larger scale beater for the fibre, and he'll definitely need to expand the land area under cultivation for mulberry fibre ...

Do I hear a most interesting Kickstarter project coming down the pipe? :-)

Added by: Marc Kahn on July 27, 2016, 2:00 am

That's really good news! I was afraid that I was going to see you have to become a papermaker, in addition to everything else you have to do yourself.

It seems to me that he might be able to scale up using your model of taking on apprentices.

Added by: Margaret Maloney on July 27, 2016, 3:49 am

That's a wonderful development! I look forward to hearing more about this in the future.

Added by: Eric F on July 27, 2016, 5:54 am

Look at the staff on their website - their "Farm Management" crew wins me over. I hope the experiment works!

Added by: Stu on July 27, 2016, 9:50 am

Wonderful news! And, hopefully, if there's one craftsman who wants to make high-quality traditional paper, there might be others out there as well!

Added by: Sam K on July 27, 2016, 10:39 am

Well, this sounds like at least a step in the right direction. I think there's a lot to be said for "crazy" enthusiasts in any trade, and especially in fine crafts. Here's hoping this leads to something great for the future of woodblock printing and papermaking.

Added by: quintin on July 29, 2016, 3:41 pm

it all sounds promising! é ‘å¼µã£ã¦

Added by: Jakub on August 6, 2016, 11:09 pm

So David you are a non-artist with no interest in preserving tradition who is preserving a traditional artform. That's quite a job description!

I wonder though if they company might be hiring if they intend to go through with your ideas. I feel working with that staff(especially the ones in the middle) would be a good experience.

Add Your Input