« First Print ... part three ... | Front Page | The First Batch ... »

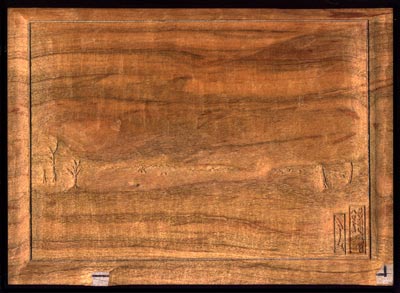

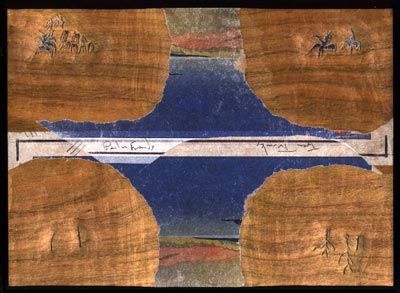

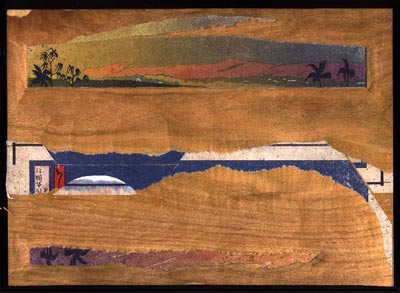

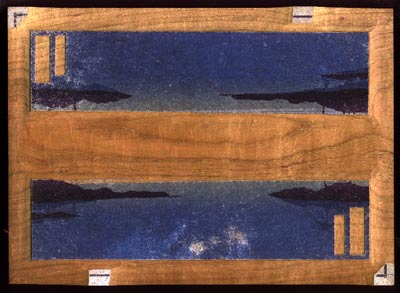

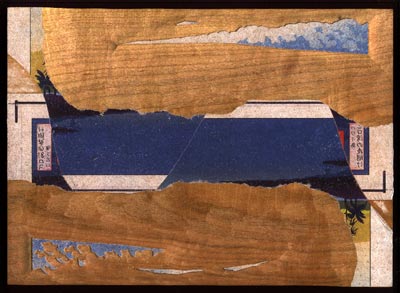

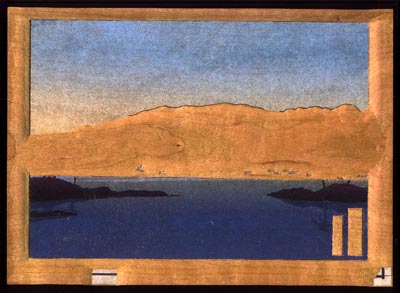

Hilo Bay [8] - block set

Posted by Dave Bull on April 1, 2006 [Permalink]

Continued from Hilo Bay [7] | Starting point of the thread is here

The block set for the Hilo Bay print is now done: five pieces of wood, ten sides, 18 'register' areas, and it'll be somewhere near 40 impressions ...

I've done a quick set of scans before washing them, as I think it might be easier for people to see what each carved area is intended to print if I leave the coloured master sheet in place on each piece of wood ...

Here they are:

This all matches the colour separation plan that I produced last week, so if you have the time to try and figure out 'what is where', then go for it!

The thread continues in Hilo Bay [9] ...

Added by: Marc on April 1, 2006, 11:55 pm

Dave, I'm confused. You say that you're done with carving and about to wash off the residual master sheet. But, none of your kento are carved yet. Does this happen later, in proofing? How do you know where the kento go if the marks from the master sheet are gone? Please explain.

Thanks,

Marc

Added by: Dave on April 2, 2006, 8:19 am

How do you know where the kento go if the marks from the master sheet are gone?

Cutting those registration marks is the job of the printer, not the carver. For those blocks in the photos above, the carver's work is done (barring any re-cuts, adjustments, errors, etc.)

The blocks will now go to the printer, who will study them, wash off the paper residue (leaving the registration marks alone), and then start proofing (this will be me, I guess ...).

Printers keep a few cutting tools at hand: the kento-nomi, for cutting and adjusting the registration marks, and a small selection of u-gouge chisels, for 'quick-n-dirty' scooping away of any areas that turn out not to be cut deeply enough.

Carvers sometimes do cut those corner marks, but printers would rather they leave them alone. Each person has his own way of holding the paper, and the microscopic positioning of the marks is very important. I can say, with no exaggeration really, that cutting those marks is perhaps the most difficult part of this entire job, and something that I still struggle with, after 25 years ...

Add Your Input